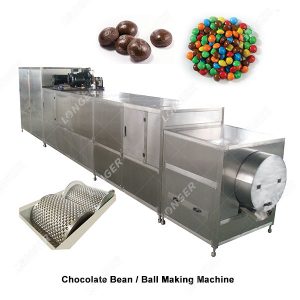

Introduction of Chocolate Panning Machine for Sale

In the chocolate and confectionery industry, this polishing pan is a key piece of equipment. It can evenly coat and polish the surface of various candies and nuts with chocolate. Furthermore, it can polish chocolates of various shapes to achieve the desired gloss and color, such as spherical, oval, star-shaped, and heart-shaped chocolates.

Functional Features of Chocolate Polishing Machine:

- Chocolate Spraying System: Equipped with a spray head, it allows for a more even application of chocolate paste to the product surface.

- Adjustable Polishing Pan Rotation Speed: Adjustable to meet different finished product requirements; speed can be adjusted by replacing the pulley.

- Selectable Cold/Hot Air Blower System: Enables rapid switching between hot and cold air, accelerating the drying and curing process of the chocolate panning.

- Precise Temperature Control System: Ensures the chocolate coating cures and sets at the optimal temperature.

- Machines are constructed from 304 or 316 grade stainless steel, ensuring food contact safety.

- Multiple Polishing Machine Models Available: Depending on the model (different pan diameters) and the materials being processed, processing capacity ranges from 8kg to 200kg per batch.

Application Range of the Chocolate Panning Machine

- Chocolate Industry: It is used for polishing chocolates of various shapes, including round, flat, oval, seed-shaped, and cylindrical, as well as in the production of M&M’s and other chocolate beans.

- Confectionery: The panning machine is suitable for coating products such as fish skin peanuts, hard candy, soft candy, and bubble gum.

Parameter of Chocolate Panner Machine

| Model | LG-CPG400 | LG-CPG1000 | LG-CPG1200 | LG-CPG1500 |

| Pot diameter(mm) | 400 | 1000 | 1200 | 1500 |

| Motor Power(kw) | 0.37 | 1.1 | 3 | 5.5 |

| Heating Power(kw) | 0.5 | 1.5 | 2 | 3 |

| Weight(kg) | 100 | 350 | 500 | 750 |

| Dimension(mm) | 500*400*800 | 1000*1000*1600 | 1200*1200*1750 | 1500*1500*1900 |

How to Use the Panning Machine?

- First add the semi-finished product, start the power supply, and the motor drives the polishing pot to rotate. After the quality meets the requirements, stop and discharge.

- During operation, slurry, brightener or polisher can be added as needed to improve gloss and ensure quality.

This polishing machine can be used in conjunction with chocolate tempering machine, storage tank, etc.

Reviews

There are no reviews yet.